PCB Materials Description and Comparison

New to PCB Prototyping, unsure which material would suit your project, or simply haven’t had experience in the materials we offer as options? Read on to learn more about FR-4 TG130, Aluminum Base, and Flexible PCB—the materials we offer for PCB prototyping.

FR-4 TG130

FR-4 is commonly used for material in PCB prototypes due to its properties and manufacturers experience with it. It provides good insulation and arc resistance—the time it takes for an insulating surface to become conductive under a high voltage/low current arc. FR-4, or Flame Retardant 4, refers not to a specific material but rather grade of material and composed by a composite of woven fiberglass cloth and flame-resistant epoxy resin binder.

TG stands for Glass Transition and is the temperature at which a PCB substrate changes from a rigid structure to a viscous one. Measured in Celsius, TG130 simply means that 130 degrees Celsius is the temperature range which would cause FR-4 TG 130 will transition to its softened state. After cooling, it will revert to its original properties. Check the parameter here.

Pros of FR-4 TG130

- Good insulation properties

- Good arc resistance

- Low water absorption

- High familiarity among manufacturers

- Most common among FR-4 materials

- When to use FR-4 TG130

When should you use FR-4 TG130?

Appropriate for most use cases where you need a rigid PCB or when you are building a product around a PCB. This is your standard, go-to material for single-layer, double-layer, and multi-layered PCBs.

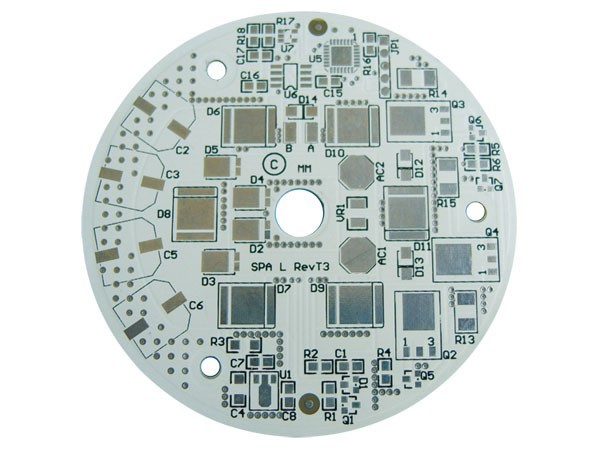

Aluminium Base

A Metal Core Board or Insulated Metal Substrate (IMS), this material provides better heat dissipation than other materials to allow surface mounted components to cool efficiently. It also carries a lower cost and density than other metal materials, so, therefore, is the metal of choice when substantial cooling is required in PCBs such as for LEDs or power switches.

Commonly as a single-sided substrate, components placed on an Aluminum based PCB will be mounted on the copper side. The structure is typically an Aluminum base, a thin insulating (dielectric) layer, followed by a circuit copper layer.

Pros of Aluminum

- Superior heat dissipation

- Resilient and durable

- Lightweight metal choice

- Lower cost metal

- A more environmentally friendly PCB material (both to manufacture and recycle)

When should you use an Aluminum Base?

If you need a metal base to dissipate high temperatures without a heat sink, such as with LEDs, Power Converters, or other high-powered electronics.

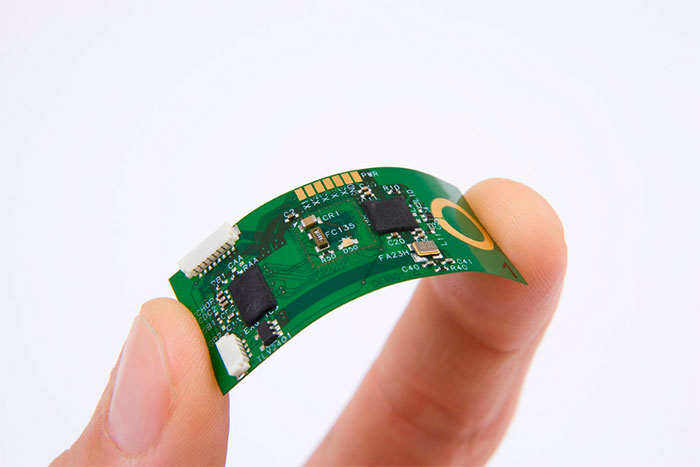

Flexible PCB

Coming in either a standalone copper-clad foil or laminated form factor, Flexible PCBs are designed to suit a product rather than building a product to suit the PCB. Flexible PCBs have allowed the rise in wearable technology which often inserts printed circuitry into tight spaces. This has in turn pushed suppliers to offer finer lines and spaces and thinner copper and base material.

Pros of Flexible PCBs

- Well, flexibility for one

- Lower weight/mass

- Smaller size for more compact products

- Ability to withstand extreme environmental conditions

- Reliability- fewer interconnects, so fewer possibilities to fail

- When to use Flexible PCB

When should you use Flexible PCB?

Flexible printed circuits are best used when there is a great limitation on space for PCBs such as in wearables or other small devices or to connect PCBs together. Because of its ability to withstand extreme conditions, it is also suitable for devices that require durability.

Your selection of PCB material will depend on the requirements and purpose of the PCB being prototyped. We offer a good selection of varying materials to suit most PCB and project needs. Whether you are creating a Rigid PCB for a more traditional application, creating for higher powered electronics, or developing IoT for shrinking devices, we can prototype your vision. Get an instant online quotation today for all your specifications.