Which PCB Material should you use?

We put together a comparison on the type of PCB Material offered here at Smart Prototyping and give you a basic rundown of why and when should you use them.

If you are new to PCB Prototyping and have no idea what these materials are, we also provide written information about these materials to give you a start. You can check it out here.

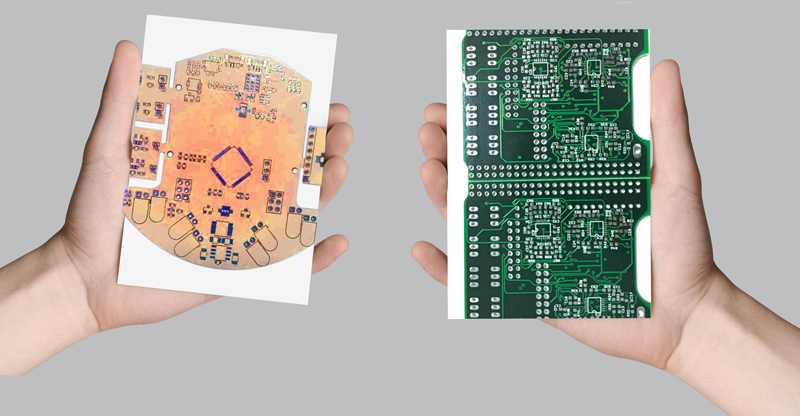

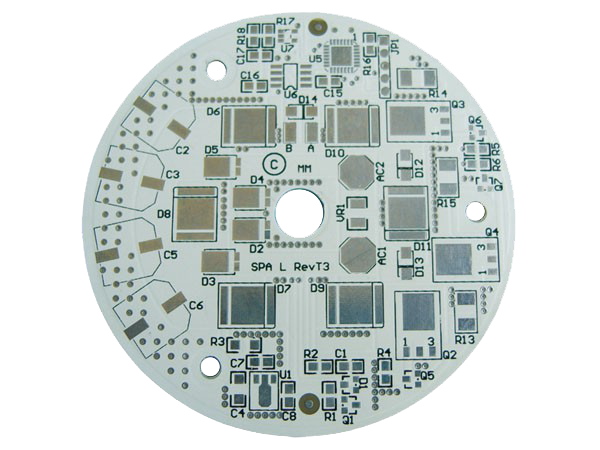

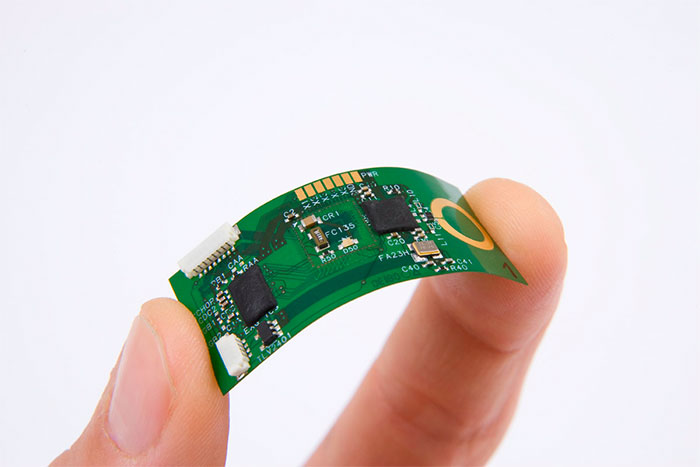

FR-4 TG130 | ALUMINIUM BASE | FLEXIBLE PCB | |

What is it? | Composed by a composite of woven fiberglass cloth and flame-resistant epoxy resin binder.

TG simply means Glass Transition and 130 is the temperature range in celcius at which the PCB changes from rigid to softened state. | Metal Core Board or Insulated Metal Substrate (IMS) | Comes in either a standalone copper-clad foil or laminated form factor |

Why use this? |

|

|

|

When to use this? | Appropriate for most use cases where you need a rigid PCB or when you are building a product around a PCB.

This is your standard, go-to material for single-layer, double-layer, and multi-layered PCBs. | If you need a metal base to dissipate high temperatures without a heat sink, such as with LEDs, Power Converters, or other high-powered electronics. | Best used when there is a great limitation on space for PCBs such as in wearables or other small devices or to connect PCBs together |

|  |  |

Your selection of PCB material will depend on the requirements and purpose of the PCB being prototyped. We offer a good selection of varying materials to suit most PCB and project needs. Whether you are creating a Rigid PCB for a more traditional application, creating for higher powered electronics, or developing IoT for shrinking devices, we can prototype your vision.

Get an instant online quotation today for all your specifications.